CNC Machining Applications in Automotive Parts: Processes & Benefits

Explore how CNC machining powers the production of automotiv...

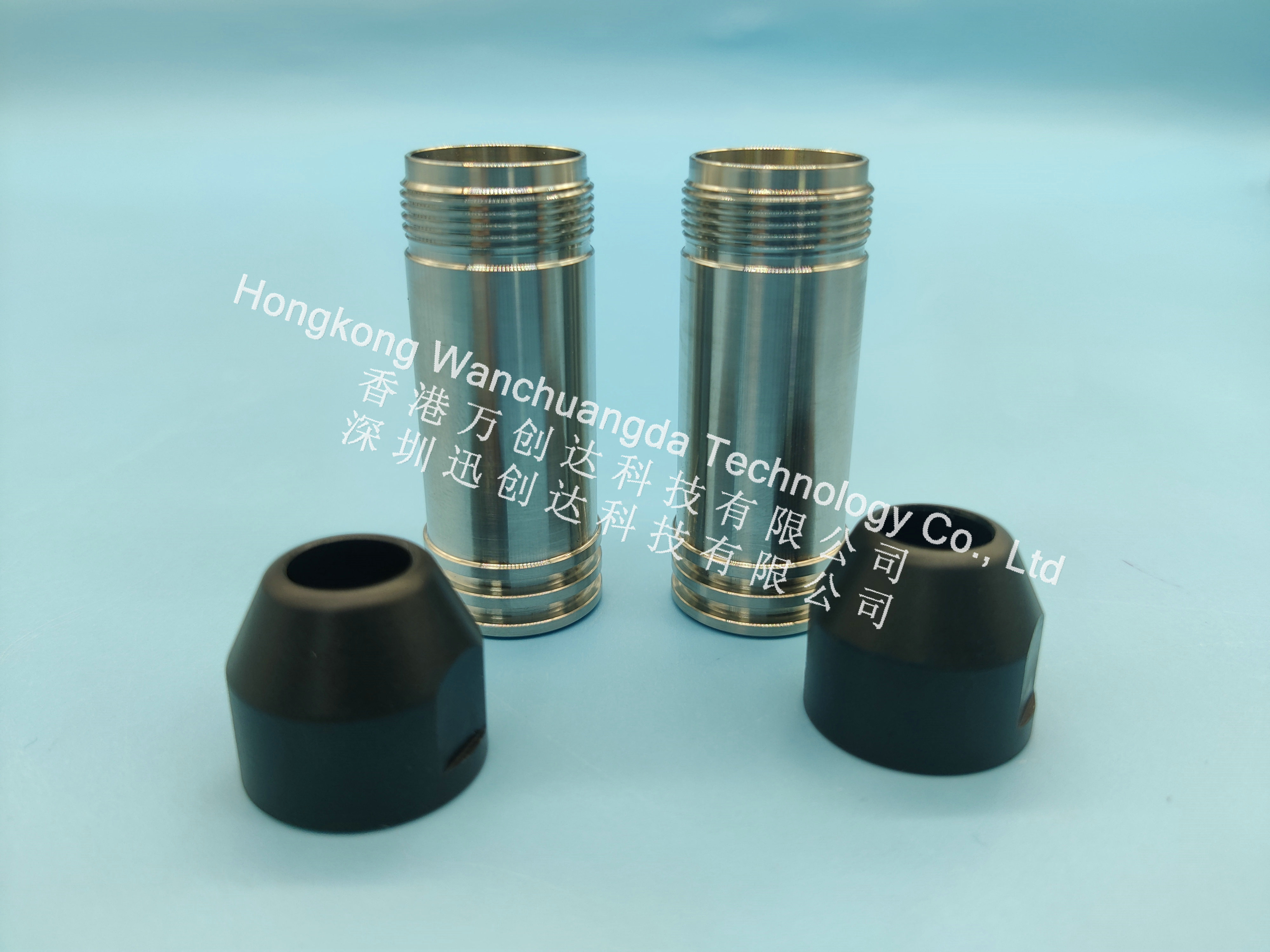

CNC turning services involve the use of computer-controlled lathes to shape materials into precise, cylindrical parts. These services are crucial in various industries, including automotive, aerospace, and medical devices, due to their ability to produce high-quality components efficiently and accurately. This article delves into the fundamentals of CNC turning, the materials used, the advantages of these services, design recommendations, surface finishes, and the wide range of applications for CNC turned parts.

CNC lathes use a subtractive method to create the desired shape. Here's a step-by-step overview:

This method allows for high precision and repeatability, making it suitable for both simple and complex geometric designs.

Types of CNC Turning Operations

CNC turning can achieve a variety of shapes and features, including:

CNC turning is a versatile process capable of producing both simple and complex parts with high precision and repeatability.

CNC turning can work with a variety of materials, each offering unique properties and benefits. Choosing the right material is crucial for the success of your project.

CNC turning machines are known for their high precision and accuracy. They can achieve tight tolerances, often within a few thousandths of an inch. This level of precision ensures that parts are made to exact specifications, which is crucial for industries like aerospace and medical devices.

Cost-Effectiveness

CNC turning is economical for both short and long production runs. The process is automated, which reduces labor costs. Additionally, one operator can manage multiple machines, further lowering expenses. This makes CNC turning a cost-effective solution for manufacturing parts.

Scalability

CNC turning services offer excellent scalability. Whether you need a single prototype or a large batch of parts, CNC turning can handle it. The process is fast and efficient, allowing for quick turnaround times. This scalability is beneficial for businesses that need to ramp up production quickly.

CNC turning machines are efficient and fast, allowing parts to get to market on time without compromising quality.

When designing parts for CNC turning, there are several key considerations to keep in mind to ensure manufacturability and performance. Here are some important guidelines:

Avoiding Long, Thin Structures

Avoid designing long, thin structures as they can deflect under cutting pressure, leading to inaccuracies. Ideally, the length-to-diameter ratio should be kept at 2 or 3 to 1. For very long parts, a steady rest can be used to support the part and reduce vibration.

Specifying Surface Roughness

When specifying surface roughness, consider the end-use of the part. A smoother finish may be required for parts that will be in contact with other components. However, achieving a very smooth finish can increase machining time and cost. It's important to balance the need for a smooth surface with the overall production efficiency.

Challenges with Deep Bored Holes

Deep bored holes can be challenging, especially when the depth-to-diameter ratio is high. Holes with a high length-to-diameter ratio may require the use of a boring bar, which can deflect if the ratio is too high. This can lead to inaccuracies and increased machining time. To avoid these issues, try to design holes with a lower depth-to-diameter ratio whenever possible.

Keeping these design recommendations in mind can help improve the manufacturability and performance of CNC turned parts, ultimately leading to better quality and reduced production time.

CNC turning offers a variety of surface finishes to enhance the appearance and performance of parts. Some common finishes include:

Tolerances in CNC turning are crucial for ensuring parts meet precise specifications. We follow ISO 2768 standards for CNC machining. Here are the typical tolerances for metals and plastics:

| Nominal Size (mm) | Plastics (ISO 2768-m) | Metals (ISO 2768-f) |

|---|---|---|

| 0.5 to 3 | ±0.1 | ±0.05 |

| Over 3 to 6 | ±0.1 | ±0.05 |

| Over 6 to 30 | ±0.2 | ±0.1 |

| Over 30 to 120 | ±0.3 | ±0.15 |

| Over 120 to 400 | ±0.5 | ±0.2 |

| Over 400 to 1000 | ±0.8 | ±0.3 |

| Over 1000 to 2000 | ±1.2 | ±0.5 |

| Over 2000 to 4000 | ±2.0 | N/A |

Improving Part Performance with Finishes

Selecting the right surface finish can significantly improve the performance of CNC turned parts. Anodizing and plating can enhance corrosion resistance, while polishing can reduce friction. Bead blasting can provide a uniform matte finish, which is ideal for parts that require a non-reflective surface.

When choosing a surface finish, consider the part's function and environment. The right finish can extend the part's lifespan and improve its performance.

CNC turned parts are essential in various industries due to their precision and versatility. Here are some key applications:

Automotive Industry

CNC turning is widely used in the automotive industry for manufacturing engine components such as cylinder heads, connecting rods, and camshafts. It is also used for transmission parts like shafts and rings, as well as suspension components including sway bars and control arms.

Aerospace Components

The aerospace industry relies on CNC turned parts for creating critical components like probes, joint connectors, and fasteners. These parts often use materials like titanium, which can withstand extreme temperatures and conditions.

Medical Devices

In the medical field, CNC turning is used to produce highly precise and reliable components for medical devices. This includes parts for surgical instruments, implants, and diagnostic equipment.

CNC turning helps in creating unique parts with great accuracy and flexibility. It can work with different materials such as metal, plastic, or composite, making it a versatile choice for various applications.

CNC turning services offer a reliable and efficient way to produce high-quality parts with precision and speed. Whether you need a single prototype or a large production run, CNC turning can meet your needs with a variety of materials and finishes. The process is ideal for creating cylindrical parts and can handle complex designs with ease. With the added benefits of cost-effectiveness and scalability, CNC turning is a valuable solution for many industries. Trust in CNC turning services to deliver the exact specifications you require, ensuring your projects are completed on time and to the highest standards.

CNC turning is a manufacturing process where a cutting tool removes material from a rotating workpiece to create cylindrical parts. A CNC lathe controls the movement, ensuring precision and repeatability.

What materials can be used in CNC turning?

CNC turning can work with a variety of materials including metals like aluminum, steel, and brass, as well as plastics like nylon and polycarbonate.

How accurate is CNC turning?

CNC turning machines are highly accurate, often achieving tolerances within a few thousandths of an inch. Advanced machines can reach even tighter tolerances.

What are the advantages of CNC turning?

CNC turning offers several benefits including high precision, cost-effectiveness, and the ability to produce parts quickly. It is also scalable for both small and large production runs.

What types of parts are best suited for CNC turning?

CNC turning is ideal for creating cylindrical parts such as shafts, hubs, and spindles. It can also handle complex designs with features like grooves and threads.

Can CNC turned parts have different surface finishes?

Yes, CNC turned parts can have various surface finishes including smooth, bead blasted, and even threaded surfaces to meet different functional and aesthetic requirements.

Explore how CNC machining powers the production of automotiv...

Discover how high-precision CNC machining enables ultra-accu...

Explore how CNC machining technology, through high precision...

Learn about the different types of metal plating processes, ...

Surface treatment technologies are integral to improving mat...

Copyright © 2024 Shenzhen Xunchuangda Precision Technology Co., Ltd. ALL Rights Reserved