Why Is CNC Machining the Core Technology in Oilfield Drill Bit Manufacturing?

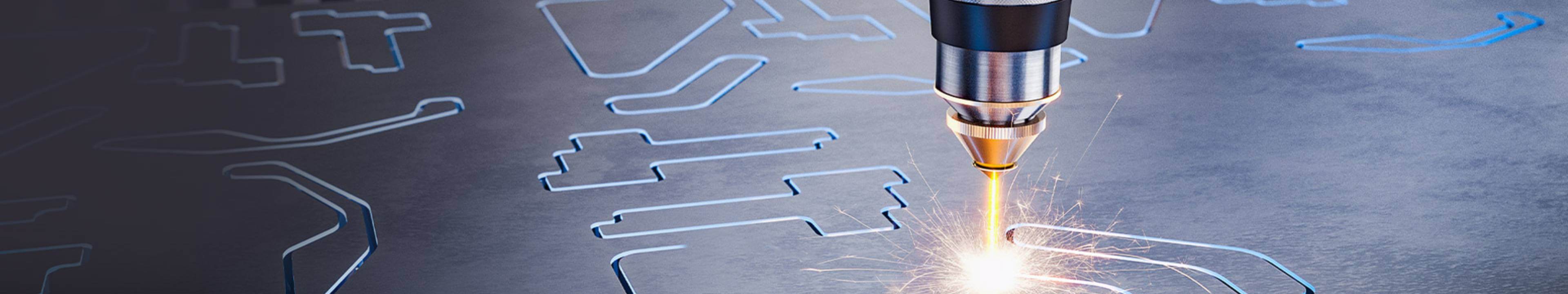

Oilfield drill bits are critical tools in oil and gas exploration, with their performance directly affecting drilling costs and efficiency. Traditional manufacturing methods struggle to meet the demands of complex formations. In contrast, CNC machining—with its micrometer-level precision, automated production, and capability to process intricate geometries—has emerged as a revolutionary solution for drill bit manufacturing.

4 Key Advantages of CNC Machining

- Micrometer-Level Precision:

CNC machines can achieve precision within ±0.005mm, ensuring that the cutting edge angles and channel designs of drill bits are exact.

- High-Efficiency Production:

Automation minimizes manual intervention, boosting production efficiency by over 40%.

- Complex Geometry Processing:

With support for multi-axis simultaneous machining, CNC technology can effortlessly process complex structures such as PDC bits and roller cone bits.

- Strong Material Adaptability:

CNC machining improves efficiency by about 30% when working with high-hardness materials such as cemented carbide and cobalt-based alloys.

3 Major Challenges in Oilfield Drill Bit Manufacturing and CNC Solutions

Challenge 1: Difficult Machining of High-Hardness Materials

- Solution:CNC machines, paired with diamond tools, optimize cutting parameters (feed rate, spindle speed) to reduce tool wear, making it possible to efficiently machine even the hardest materials.

Challenge 2: Demand for Complex Geometries

- Solution:Five-axis CNC technology enables multi-edge cutting and the creation of asymmetric channels, which significantly enhances chip removal efficiency and meets the intricate design requirements of modern drill bits.

Challenge 3: Consistency in Mass Production

- Solution:By using precise G-code programming, CNC machining ensures that each drill bit has a dimensional error of less than 0.01mm, thereby reducing the risks associated with downhole operations.

How Does CNC Technology Enhance Oilfield Drill Bit Performance?

- Improved Wear Resistance:

Precision machining achieves a cutting edge surface roughness of Ra < 0.4μm, which minimizes friction losses during drilling.

- Optimized Drilling Speed:

Accurate cutting angles can boost drilling speeds by 15–20%, significantly enhancing overall drilling efficiency.

- Reduced Maintenance Costs:

With a lifespan that is 1.5 times longer than drill bits produced using traditional methods, CNC-machined drill bits reduce downtime and maintenance expenses.

Future Trends: The Integration of CNC and Smart Manufacturing

- Additive Manufacturing + CNC Composite Machining:

The combination of 3D-printed drill bit bases with CNC precision finishing can shorten delivery cycles by 30%.

- AI Real-Time Monitoring:

Sensors collect real-time cutting data to dynamically adjust machining parameters, thereby preventing tool breakage.

(Keyword: intelligent drill bit manufacturing)

- New Material Applications:

The use of tungsten carbide coatings combined with CNC ultra-precision machining is pushing the high-temperature performance of drill bits beyond 800°C.

Frequently Asked Questions (FAQ)

Q1: Are oilfield drill bits machined by CNC suitable for deep well operations?

A: Yes. CNC technology can be used to customize high-pressure-resistant structures. For instance, the XX model drill bit shows a 22% reduction in wear when used in 8000-meter deep wells.

Q2: Are CNC drill bit manufacturing costs higher?

A: Although the initial equipment investment is high, mass production via CNC machining can lower the per-unit cost by 35%, offering significant long-term benefits.

By leveraging CNC machining, the oil and gas industry can achieve unparalleled precision and efficiency in drill bit manufacturing. This technology not only meets the rigorous demands of modern drilling operations but also paves the way for future innovations in intelligent and high-performance manufacturing.