CNC Machining Applications in Automotive Parts: Processes & Benefits

Explore how CNC machining powers the production of automotiv...

Vacuum casting, also known as polyurethane (PU) casting, is a widely used manufacturing process for producing high-precision, small-batch parts or prototypes. This process injects liquid material into a silicone mold under vacuum conditions to ensure the final part is free of air bubbles or defects. Additionally, vacuum casting offers a wide variety of material options to meet different performance and functional requirements for the final product. Commonly used vacuum casting resins include ABS-like resins, PC (polycarbonate)-like resins, PMMA materials, and soft rubbers. This article will help you understand the characteristics of these resins and assist you in making the best material choice for your project.

The performance of the final vacuum-cast product is directly influenced by the selected material. The unique properties of each material determine the functionality, aesthetics, and durability of the cast parts. Different materials possess varying levels of flexibility, strength, hardness, appearance, heat resistance, and optical transparency, all of which impact the final product's effectiveness.

Material selection is crucial for the performance and lifespan of vacuum-cast parts. For example, materials with high tensile strength and heat resistance are suitable for parts exposed to high temperatures or stress. In contrast, materials with better flexibility and impact resistance are more suitable for applications that require adaptability and shock absorption.

The fluidity of the material determines the surface quality of the cast part. If the molten material fills the mold smoothly, the final product will have a smoother and more attractive surface. This is particularly important for parts with high aesthetic requirements, such as consumer electronics and premium automotive components.

Material costs are a significant factor that influences the overall project budget. The more expensive the chosen material, the lower the cost-effectiveness of the project. However, some materials, although less expensive, can still provide excellent quality, making them suitable for prototype production and small-batch manufacturing.

The selected material must match the application requirements. For example, medical devices require biocompatible materials, while outdoor applications may require UV-resistant materials. The production cycle also varies depending on the material; some may be better suited for small-batch rapid production.

After understanding the importance of materials, let's explore some common vacuum casting materials to help you choose the right resin.

ABS-like resins provide strength, durability, and thermal stability, producing parts with smooth surfaces and structural stability. They are suitable for products that require both appearance and strength, such as consumer goods and industrial applications.

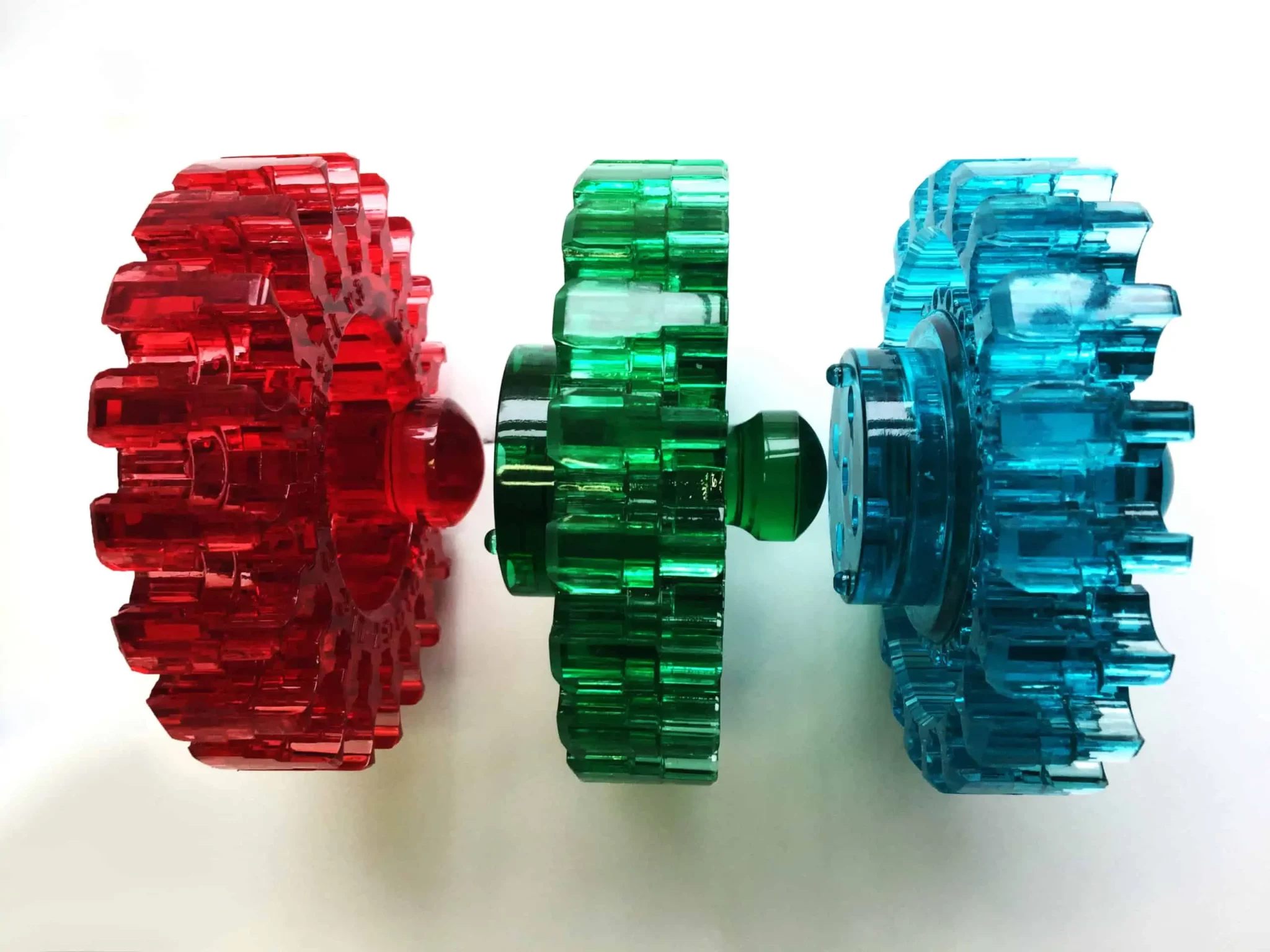

PC-like resins offer the transparency and strength similar to polycarbonate, making them ideal for manufacturing high-precision, impact-resistant, transparent parts and applications requiring optical clarity.

PP-like resins are known for their thermal stability, low weight, and chemical inertness, making them suitable for applications that require flexibility and fatigue resistance.

PMMA is renowned for its optical transparency, mechanical strength, and scratch resistance, making it commonly used for producing optical components or protective covers that require high transparency.

Transparent soft rubber combines the flexibility of rubber with the transparency of glass, making it ideal for complex parts requiring both clarity and flexibility.

Below is a comparison table of common vacuum casting materials. This table provides a clearer overview of each material’s key properties and applications, making it easier for you to select the right material for your project.

Material Type | Material Grade | Key Properties | Typical Applications | Remarks |

ABS-like Resin | PU8150 | Wear-resistant, chemical-resistant, high strength, semi-transparent | Various seals, hoses, industrial equipment components | High wear resistance, suitable for mechanical equipment applications |

PU8260 | High impact resistance, flame retardant, good elasticity | Automotive seals, protective casings, electronic device enclosures | Flame retardant, ideal for automotive and electronic fields | |

PU8263 | High-temperature resistance, excellent mechanical properties | Industrial equipment and automotive parts for high-temperature environments | Suitable for complex industrial environments | |

PC-like Resin | PU8098 | High-temperature resistance, impact resistance, UV resistance | Automotive bumpers, dashboards, industrial components | Replaces polycarbonate, suitable for transparent parts |

PX510 | High strength, UV resistance, excellent thermal stability | Transparent prototypes, electronic device housings, lighting fixtures | Ideal for outdoor applications and high-transparency needs | |

UP6160 | High-temperature resistance, easy to process | Lightweight automotive components, electronic device enclosures | Suitable for parts with complex shapes | |

PP-like Resin | PU8570 | High wear resistance, flexibility, impact resistance | Mechanical seals, automotive interiors, connectors | Suitable for high-strength flexible components |

PMMA (Acrylic) Materials | PX5210HT | High transparency, low shrinkage, excellent UV resistance | Automotive lighting, medical device components, optical lenses | Ideal for applications requiring high appearance and transparency |

X522HT | High thermal stability, impact resistance, excellent transparency | Aerospace components, outdoor lighting equipment | Suitable for transparent materials that endure harsh environments | |

Transparent Soft Rubber | UPX8400 | High elongation, easy to process, good tear resistance | Medical prototypes, wearable device components, automotive lighting | Suitable for applications with high requirements for flexibility and transparency |

Factors Affecting Material Selection for Vacuum Casting

When selecting materials, it’s essential to consider various influencing factors. Below are some key points:

Environmental Factors:Consider the part's working environment, as material performance varies under different humidity, temperature, chemical exposure, and UV exposure conditions. For example, PC-like PX510 resin has excellent UV resistance, making it suitable for outdoor applications.

Cost Factors:Material prices can vary significantly, affecting the overall project budget. High-performance materials are more expensive, but are essential for applications requiring strict performance requirements.

Production Volume and Lead Time:Production volume and lead time can also influence material selection. Some materials are suitable for small-batch production and offer shorter molding cycles, while complex materials

How to Choose the Right Material for Your Vacuum Casting Project

After understanding common vacuum casting materials and their selection factors, you can choose the right material based on your project's specific needs. Environmental conditions, physical properties, production volume, and budget are key factors to consider.If you are unsure which material is best suited for your project, it is recommended to consult with a professional vacuum casting supplier or engineer. With years of experience, RapidDirect can provide detailed manufacturability design analysis and recommend the best vacuum casting materials for your project. You can upload your design files at any time to receive professional advice.

Explore how CNC machining powers the production of automotiv...

Discover how high-precision CNC machining enables ultra-accu...

Explore how CNC machining technology, through high precision...

Learn about the different types of metal plating processes, ...

Surface treatment technologies are integral to improving mat...

Copyright © 2024 Shenzhen Xunchuangda Precision Technology Co., Ltd. ALL Rights Reserved