CNC Machining Applications in Automotive Parts: Processes & Benefits

Explore how CNC machining powers the production of automotiv...

Introduction of CNC Machining Technology

1. Basic Principle of CNC Machining

CNC Machining (Computer Numerical Control Machining) uses computer numerical control technology to operate mechanical processes. This technology controls mechanical equipment and the machining process using digital information. CNC machines automatically execute material cutting based on pre-set programs, typically written in programming languages like G-code, ensuring precision and automation in the machining process.

2. Types and Applications of CNC Machines

CNC machines are widely used in various manufacturing industries, including automotive, aerospace, mold manufacturing, and medical equipment. Based on different processing objects and methods, CNC machines can mainly be categorized as follows:

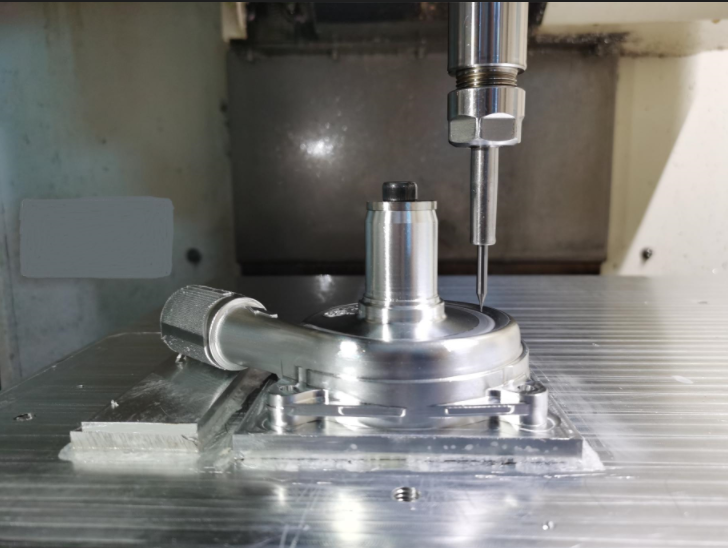

CNC Milling Machines: Used for complex cutting tasks, such as machining surfaces and intricate contours.

CNC Lathes: Mainly used for the cylindrical cutting of rotating workpieces.

CNC Drilling Machines: Used for drilling holes in workpieces.

CNC Grinding Machines: Used for high-precision surface finishing.

3. Advantages of CNC Machining

High Precision: CNC machining can achieve extremely high accuracy and consistency, with errors controlled within micrometers.

High Degree of Automation: Once programmed, CNC machines can continuously operate without manual intervention, significantly improving production efficiency.

High Flexibility: By changing CNC programs, production setups can be quickly adjusted to meet different production needs.

Reduced Labor Costs: Although the initial investment is high, it can reduce manual operation costs in the long run.

4. Common Machining Materials

CNC machines can process a variety of materials, including but not limited to:

Metals: Aluminum, steel, copper, titanium, etc.

Plastics: Nylon, ABS, polycarbonate, etc.

Wood: Capable of finely machining complex wooden products.

5. Future Development of CNC Machines

With the advancement of smart manufacturing and Industry 4.0, CNC technology is evolving towards higher automation and intelligence. Future CNC machines will integrate more sensors and AI algorithms to further improve machining accuracy and efficiency.

Explore how CNC machining powers the production of automotiv...

Discover how high-precision CNC machining enables ultra-accu...

Explore how CNC machining technology, through high precision...

Learn about the different types of metal plating processes, ...

Surface treatment technologies are integral to improving mat...

Copyright © 2024 Shenzhen Xunchuangda Precision Technology Co., Ltd. ALL Rights Reserved