CNC Machining Applications in Automotive Parts: Processes & Benefits

Explore how CNC machining powers the production of automotiv...

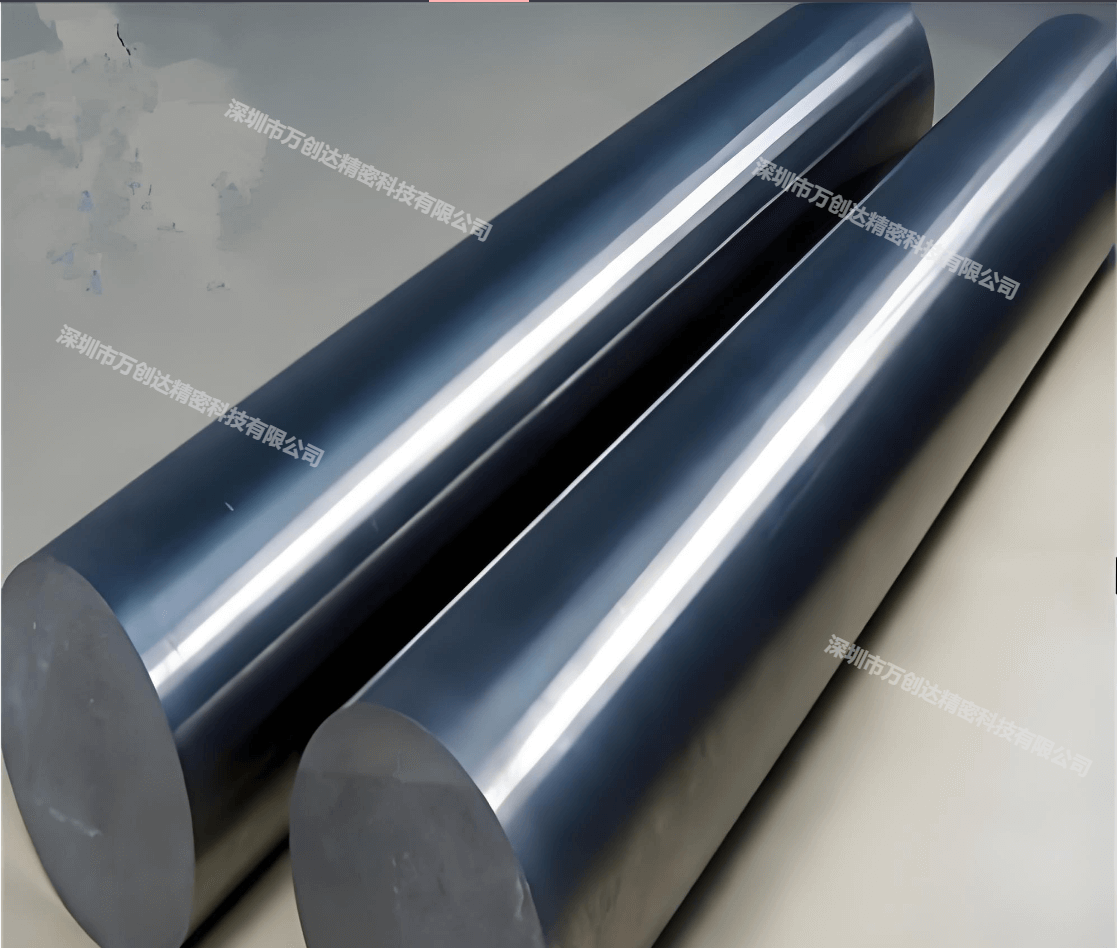

What is Steel CNC Machining?

When we mention CNC machining or steel, it's straightforward. However, combining steel with CNC technology might be confusing to many. In essence, CNC machining involves placing materials or components on a CNC machine to follow specific tool paths. Steel CNC machining refers to using CNC technology to process steel objects, achieving the desired shape or product.

Application and Impact of CNC Machining in the Steel Industry:

Steel is a category of metals, and discussing CNC machining in steel can be better understood by exploring its impact on the metal industry as a whole. As technology progresses rapidly, CNC technology has found extensive applications in the steel industry.

CNC machining technology offers numerous benefits. It not only enhances production efficiency but also reduces errors caused by human factors, achieving high precision and quality. In the context of steel processing and applications, the impact is significant:

Precision Parts Production:CNC technology enables high-precision machining of steel parts by controlling tool paths and cutting methods, improving product quality and stability.

Mold Manufacturing: In mold making, CNC technology reduces production time and enhances the accuracy and quality of molds.

Precision and Artistic Metalwork: CNC technology allows for high-precision engraving on metals, making complex designs and detailed patterns possible.

With the rapid development of CNC technology, its advantages in steel processing are evident.

Advantages of Steel CNC Machining:

Increased Efficiency: CNC machining technology significantly boosts processing efficiency by automating the production of parts and molds, reducing labor and time costs, and improving production quality and consistency.

High Precision: CNC systems provide precise control with improved resolution, minimizing errors and ensuring accuracy and precision.

Enhanced Durability: CNC steel parts have notable corrosion and wear resistance, extending the lifespan and usage cycle of components.

Versatility: CNC machining systems offer strong adaptability and control, allowing for adjustments in parameters and operation methods to handle complex and high-precision products.

Disadvantages of Steel CNC Machining:

The drawbacks are not specific to steel but pertain to CNC technology as a whole. CNC machines are expensive, and maintenance requires specialized skills, leading to higher repair and maintenance costs. General operators may not be able to handle repairs, necessitating professional maintenance services.

Common Types of Steel:

Steel can be categorized based on carbon content into low-carbon steel, medium-carbon steel, and high-carbon steel. Common carbon structural steels include Q195, Q215, Q235, Q255, and Q275.

Mechanical Properties of Common Steel Grades:

45 Steel (Medium Carbon Tempered Steel):Known for its excellent mechanical properties, it has low hardenability and can develop cracks during water quenching. Small parts are often tempered, while larger parts may be normalized.40Cr (Alloy Structural Steel):Requires tempering to achieve good performance. It has stringent requirements for welding temperature and surface hardening to prevent cracks.

Common Uses: Spindles, heart shafts, crankshafts, etc.

1. Material Selection: Careful consideration of stainless steel characteristics is essential for choosing the right material for appropriate processing.

2. Process Selection: CNC machining requires specific knowledge for cutting, welding, polishing, and other processes to match the needs.

3. Quality Control:Quality control is crucial, with strict adherence to relevant procedures and standards during operations.

Steel CNC machining technology is highly advanced and widely applied, with sophisticated techniques used in practical applications.

At our company, we have skilled CNC operators with extensive practical experience and advanced CNC machinery. If you have any CNC or mold-related needs, contact us to collaborate and achieve sustainable development in technology and manufacturing.

Explore how CNC machining powers the production of automotiv...

Discover how high-precision CNC machining enables ultra-accu...

Explore how CNC machining technology, through high precision...

Learn about the different types of metal plating processes, ...

Surface treatment technologies are integral to improving mat...

Copyright © 2024 Shenzhen Xunchuangda Precision Technology Co., Ltd. ALL Rights Reserved